- Home /

- Domestic Tapware /

- Heritage® /

- Exposed Shower & Bath Sets /

- Heritage Alcove Shower Set with Gooseneck Riser

Heritage Alcove Shower Set with Gooseneck Riser includes a ball jointed shower rose, exposed breech and pipework and two tap assemblies.

Riser sections can be cut down to preferred length on installation.

Installation Requirement:

Plumber to supply and install two 1/2" BSP male threads at 150mm centres.

If replacing an existing similar tapware set it is likely these fittings will be pre-existing in the wall. Please consult with your plumber.

International customers please consult with our sales staff as further components and adapters may be required.

| Product Function | Exposed Shower Set |

|---|---|

| Style Association | Heritage |

| Material | DR Brass |

| Handle Type | Cross Handle |

| Spindle Type | Splined Spindle |

| Cartridge / Valve | Jumper Valve |

| Turning Type | Full Turn Standard Action, is upgradable to Rapid Action (1/4 Turn) with Hydroseal Valve |

| Outlet Type | Ball Joint Rose |

| Outlet Styling | Ball Joint Shower Arm |

| Outlet Reach (mm to Aerator or Rose) | 180 |

| Water Efficiency Star (WELS) Rating | 3 Stars (Rose) |

| Flow Rate (Litres Per Minute) | 9 Litres Per Minute |

| Suitable for Gravity Feed | No, Contact CB for Assistance |

| Suitable for Hot Water Units | Yes |

| Maximum operating pressure (kPa) | Suitable for High/Mains Pressure / 500 kPa (Australian Standards AS/NZS 3500 and the Plumbing Code of Australia) |

| Maximum Working Temperature (Degree C) | 65 |

| Relevant Standards | AS 3718:2021 |

| Quantity Unit of Measure | Set |

| Warranty | 5 Years |

| WELS Licence | WELS Licence 0091 |

| WELS Registration | S03459 (V) |

The following turnaround times are based on average turnaround and can vary depending on production load.

Turnaround times are divided between manufacturing time and transport time.

Manufacturing Turnaround Times

Typically standard items will be manufactured within 2 to 4 weeks, depending on the metal finish and production load.

Smaller items such as basin sets, 3 piece shower sets, accessories and spare parts in Antique Brass (AB), Chrome Plate (CP), Raw Brass (RB) and Polish to Plate (PP) may ship from Adelaide within a couple of weeks from order as we hold a reasonable amount of assembled stock (or near finished) for these metal finishes.

Typically manufactured to order item turnaround times will vary between 3 to 5 weeks, depending on the metal finish and production load. Some exposed tapware sets may also have this type of turnaround time, especially at times when demand for these more complicated to manufacture sets is high.

If specific turnaround times are required please contact our office to discuss further and see what is possible.

Transit Turnaround Times

South Australia

We use a local courier service within Adelaide and surrounding areas, local orders leave our factory each morning and are usually delivered same day or at latest by the following day.

If items are needed urgently locally they can be arranged for collection from our factory once ready. If intending to do this please contact our office.

For regional South Australia we use a next day road courier service with pickups from our factory occurring each afternoon.

Australia Wide

For interstate deliveries we use multiple national couriers to deliver our products via road, rail and air.

Items that can be sent around Australia in 1kg, 3kg or 5kg airbags usually have a next day delivery time frame (it can be 2 ~ 3 days for regional areas).

Bulkier items are sent via road and will usually follow the following transit times:

1 ~ 2 days for Victoria.

2 ~ 3 Days for New South Wales, Tasmania and the Australian Capital Territory.

4 ~ 6 days for Queensland, Western Australia and Northern Territory.

These delivery times are to be used as a guide, they can be subject to factors that are outside of our control such as transport strikes, traffic accidents, natural disasters, pandemics, or other out of the ordinary disruptions.

If faster transit for bulkier items is needed within Australia, there are air service options available at additional charge, please contact our office to arrange. Please note that some longer or odd packed shape items (like certain shower curtain rails) are not suitable for air transit and can only transit by road.

International

International courier services are selected per specific order requirements and per region. Where possible an economy air service is used and transit from Adelaide is between 7 to 14 days.

ABAntique Brass

Antique BrassFinish Code: ABNon-TarnishingMore Info

ABAntique Brass

Antique BrassFinish Code: ABNon-TarnishingMore Info

PBPolished Brass

Polished BrassFinish Code: PBMaturing FinishMore Info

PBPolished Brass

Polished BrassFinish Code: PBMaturing FinishMore Info

RBRaw Brass

Raw BrassFinish Code: RBMaturing FinishMore Info

RBRaw Brass

Raw BrassFinish Code: RBMaturing FinishMore Info

PPPolish to Plate

Polish to PlateFinish Code: PPMaturing FinishMore Info

PPPolish to Plate

Polish to PlateFinish Code: PPMaturing FinishMore Info

LWLea Wheeled Brass

Lea Wheeled BrassFinish Code: LWMaturing FinishMore Info

LWLea Wheeled Brass

Lea Wheeled BrassFinish Code: LWMaturing FinishMore Info

DABDull Antique Brass

Dull Antique BrassFinish Code: DABNon-TarnishingMore Info

DABDull Antique Brass

Dull Antique BrassFinish Code: DABNon-TarnishingMore Info

BABBrushed Antique Brass

Brushed Antique BrassFinish Code: BABNon-TarnishingMore Info

BABBrushed Antique Brass

Brushed Antique BrassFinish Code: BABNon-TarnishingMore Info

SABSatin Antique Brass

Satin Antique BrassFinish Code: SABNon-TarnishingMore Info

SABSatin Antique Brass

Satin Antique BrassFinish Code: SABNon-TarnishingMore Info

WBWeathered Brass

Weathered BrassFinish Code: WBMaturing FinishMore Info

WBWeathered Brass

Weathered BrassFinish Code: WBMaturing FinishMore Info

ACAB with Chrome Trim

Antique Brass

ACAB with Chrome Trim

Antique Brasswith Chrome TrimFinish Code: ACNon-TarnishingMore Info

CPChrome Plate

Chrome PlateFinish Code: CPNon-TarnishingMore Info

CPChrome Plate

Chrome PlateFinish Code: CPNon-TarnishingMore Info

BSBrushed Satin

Brushed SatinFinish Code: BSNon-TarnishingMore Info

BSBrushed Satin

Brushed SatinFinish Code: BSNon-TarnishingMore Info

SCPSatin Chrome Plate

Satin Chrome PlateFinish Code: SCPNon-TarnishingMore Info

SCPSatin Chrome Plate

Satin Chrome PlateFinish Code: SCPNon-TarnishingMore Info

NPNickel Plate

Nickel PlateFinish Code: NPNon-TarnishingMore Info

NPNickel Plate

Nickel PlateFinish Code: NPNon-TarnishingMore Info

BNBrushed Nickel Plate

Brushed Nickel PlateFinish Code: BNNon-TarnishingMore Info

BNBrushed Nickel Plate

Brushed Nickel PlateFinish Code: BNNon-TarnishingMore Info

CAChrome with AB Trim

Chrome Plate

CAChrome with AB Trim

Chrome Platewith AB TrimFinish Code: CANon-TarnishingMore Info

BCBright Copper

Bright CopperFinish Code: BCMaturing FinishMore Info

BCBright Copper

Bright CopperFinish Code: BCMaturing FinishMore Info

DCDull Copper

Dull CopperFinish Code: DCMaturing FinishMore Info

DCDull Copper

Dull CopperFinish Code: DCMaturing FinishMore Info

FBFlorentine Bronze

Florentine BronzeFinish Code: FBMaturing FinishMore Info

FBFlorentine Bronze

Florentine BronzeFinish Code: FBMaturing FinishMore Info

MBMatte Black with CP Trim

Matte Black

MBMatte Black with CP Trim

Matte Blackwith CP TrimFinish Code: MBNon-TarnishingMore Info

MAMatte Black with AB Trim

Matte Black

MAMatte Black with AB Trim

Matte Blackwith AB TrimFinish Code: MANon-TarnishingMore Info

Custom FinishesBespoke Colour Options

Custom FinishesBespoke Colour OptionsMore Info

Custom FinishesBespoke Colour Options

Custom FinishesBespoke Colour OptionsMore Info

Coloured inserts allow for increased customisation for certain ranges of our tapware and our Olde Adelaide accessories. Our coloured inserts are not plastic or ceramic, they are made from brass.

The insert finishes listed below are non-tarnishing.

There are four types of coloured insert available in our ranges. Options appear in the online catalogue where they are available for selection and addition to a product.

| Handshower Handle Inserts |

|

| Roulette Lever Coloured Inserts |

|

| Windsor Accessory Colour Inserts |

|

| Windsor Inserts for Roulette, Heritage & Roulette Lever (Priced on Special Request) |

|

White Insert Example

White Insert Example

Almond Ivory Insert Example

Almond Ivory Insert Example

Gloss Black Insert Example

Gloss Black Insert Example

Matte Black Insert Example

Matte Black Insert Example

Heritage Green Insert Example

Heritage Green Insert Example

Burgundy Insert Example

Burgundy Insert Example

As a starting point the best reference of what may be possible is the Dulux Alphatec and Duralloy colour charts. Custom colours are priced on application.

Rapid Action® (in Summary)

Rapid Action® performs the same turning action as ceramic disc but the maintenance is cheaper and easier.

Rapid Action® tapware:

- opens and closes in quarter to half a turn.

- is standard with all Roulette Lever (excluding Roulette Lever Single Lever Mixers), Torrens Ranges, Celestial Lever, and CB Ideal Seaview Series tapware.

- is available with all other ranges on request (excluding Roulette Lever Single Lever Mixers & the DB Mixer Series) .

- is suitable for low-pressure hot water supply, tank or bore with pressure pump.

Why did we develop it?

For ease of maintenance.

It uses a hydroseal valve and standard BS110 o-rings. A handyman or handywoman can change a hydroseal valve in the same manner as a normal jumper valve, and it is available from hardware shops. Packets of BS110 o-rings are also available here. The ceramic disc system needs a plumber and the appropriate kit for the model tap. Installation & servicing instructions for Rapid Action® spindles are supplied with the tapware and are also available for download here.

Rapid Action® (in Detail)

| Standard CB Spindle | CB Rapid Action Spindle | |

|

|

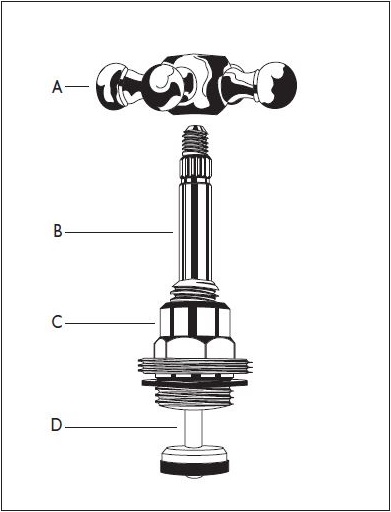

| Question: | What is Rapid Action? |

| Answer: | This term describes the mechanism which enables the tap to be fully opened or closed in less than half a turn. In conventional tapware the handle (A) turns the spindle (B) 3 to 4 full rotations up or down the thread inside the bonnet (C) and this raises or lowers the valve (D) which either lets water through the seat of the tap or shuts it off. In ceramic disc tapware the valve is replaced by ceramic discs which slide over each other (think of the twist-caps on salt and spice dispensers). When the tap is closed the ceramic discs completely cover the tap seat; when the tap is opened the discs slide to cover each other and so leave an opening which allows water to flow. In ‘Rapid Action’ tapware the handle (A1) turns the spindle (B1) up or down the specialized and very accurately machined thread inside the bonnet (C1), which enables the spindle to rise to the full open position in less than half a turn of the handle. The valve (D1), which therefore either completely opens or closes the tap seat, is of a specialized type, and very accurately manufactured, which provides a perfect seal when the tap handle is closed (without the need for extra-hard turning of the handle which often happens with conventional tapware). ‘Rapid Action’ tapware demonstrates high quality and accuracy of manufacture, and the design also allows for ease of maintenance. The Hydroseal valves (available at all good hardware stores) can be changed as easily and quickly as in a conventional tap. Packets of BS110 o-rings are also available here. Because there are a number of different ceramic disc systems on the market (all imported) it can be quite difficult to find and then fit the exact replacement part when the need arises. Installation & servicing instructions for Rapid Action® spindles are supplied with the tapware and are also available for download here. |

| Question: | Do ‘Rapid Action’ taps turn on and off the same way as ordinary taps? |

| Answer: |

If they look like ordinary taps, they turn like ordinary taps too – both hot and cold turn on anticlockwise and off clockwise. With lever tapware (Celestial Lever, Torrens Lever, Torrens Flared Lever and Roulette Lever) the hot tap turns in the opposite direction to the cold. Reference diagrams of which way the lever tapware will turn can be found here: Rapid Action Turning Directions |

| Question: | Does ‘Rapid Action’ Tapware turn through a quarter turn or a half turn? |

| Answer: | More than a quarter turn (because a quarter turn gives no graduation – the water is either off or on) and less than a half turn (because this would make the longer levers very uncomfortable to use). |

| Question: | Is ‘Rapid Action’ Tapware suitable if there is low-pressure hot water supply, or if the supply is from a tank or bore by means of a pressure pump? |

| Answer: |

Yes, because the design allows the full flow that is possible through the seat of the tap when the tap is fully open. Ceramic discs restrict the flow somewhat, even when the tap handle is in the fully open position. When the hot water supply is low pressure and the cold water is at high pressure, it may be more difficult to achieve a comfortable mixture because there is not enough graduation in less than half a turn to control the high pressure cold water – in such a situation a conventional CB standard action tap would probably be more successful.

|

A note about Rapid Action® for the Heritage® collection |

|

|

When upgrading Bib / Pillar Spindles on Heritage from Standard Action to Rapid Action, the look will change from the standard Heritage® bell shape bonnet to then use the sheath cover from the Roulette® Series. |

|

As of the 12th of March 2015, we, CB Ideal Tapware Pty Ltd have upgraded our standard warranty from 12 months to 5 years per the terms outlined below. This warranty statement superceeds that shown in the 2014 Price Book and a copy is included with applicable products sold after this date.

Warranty Statement

We (the above-named Company) accept responsibility for any fault due to our own materials or workmanship except for subjective variations or random unavoidable blemishes of a minor non-functional nature. This acceptance of responsibility is for five years from date of installation, proof of which may be required. The product (concealed or exposed) will be repaired or replaced at no cost, provided that in-wall fittings are fully tested and have also been manufactured by the Company.

This warranty does not cover misuse of the product or damage incurred during installation. Our products are made to Australian Standards and are designed to be used to a maximum temperature of 65 degrees Celsius and to a maximum operating pressure of 500kPa at any outlet within a building (Refer to Plumbing Code of Australia - AS/NZS:3500). The warranty is voided if the product is used above these limits. To make a claim the consumer should return to the seller of the product for advice, and to establish proof of purchase. The seller will then contact us, and our representative will contact the consumer to arrange whatever after-sales service is required. The consumer’s cost for making a warranty claim (e.g. freight) is discussed at the same time.

For after-sales service the consumer may also contact us direct at:-

CB Ideal Tapware Pty Ltd.

1a Deloraine Road, Edwardstown S.A. 5039

Ph: 08 8276 6766 Email: sales@cbideal.com.au

This warranty is in addition to other rights and remedies under law:

“Our goods come with guarantees that cannot be excluded under Australian Consumer Law. You are entitled to a replacement or refund for a major failure and for compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and this failure does not amount to a major failure.”

Installation and Maintenance – effect on warranty

The company provides installation instructions for certain products as a guide to the qualified tradesman/installer, but accepts no liability whatsoever for faulty installation.

The Company provides care instructions for various finishes; however because the actions of the user are outside the Company’s control it accepts no liability for deterioration of finishes outside the warranty period.

Please consider the following factors before the warranty is invoked.

| • | Any work on the water pipes can cause grit or shavings to be inside the pipes. Usually pipes are flushed to remove debris, but if any remains it may lodge in the aerator or underneath the tap valve. |

| • | The aerator case has a fine thread. If the aerator has to be removed then great care should be taken to ensure that the thread is not crossed when the case is replaced. |

| • | Lever taps are set correctly in our factory, but may need to be reset if altered during installation. The leaflet included with each lever set explains this very simple operation which is really part of the installation process. |

Maintenance, Care Instructions & Troubleshooting

The longevity of your tapware and accessories is greatly influenced by how they are cared for. Click here to view maintenance & care instructions as well as some troubleshooting tips.

Other useful FAQ sections can be found here.

Related Sections

Conditions of Sale